PIG MOLDS

If It's Metal, We Have Made a Mold For It

When it comes to all things metal, we stand unrivaled. Since 1938, the Pottstown division of Dynaform Technologies has been at the forefront, crafting air-cooled and water-cooled ingot molds, sow molds, pig molds, slag pots, and slag molds for secondary smelters worldwide. Our relentless pursuit of expertise, unparalleled quality, and unwavering attention to detail sets us apart.

Dynaform Technologies molds have earned acclaim among Secondary Smelter professionals for their unmatched durability and impeccable design. With extended lifecycles that elevate production and performance, they become catalysts for saving valuable time and resources.

Our pig molds can be cast in a broad range of shapes and sizes and from a variety of alloys, including (but not limited to):

- Cast Iron

- Ductile Iron

- Steel

- Aluminum

Your Best Choice For Custom PIG Mold Designs

Embrace the power of your unique vision. Whether you have your own custom design or seek inspiration, Dynaform Technologies stands ready to bring it to life. Our team of skilled and experienced designers is here to assist you, ensuring that you never compromise on quality and reliability.

The Process of a Custom Sow Mold Design

You present us with your specific requirements

We create an initial technical drawing

You approve or suggest changes to the technical drawing

We build a suitable pattern which meets your design criteria

We cast, machine and assemble your mold (if required)

From the initial consultation to our finished mold, Dynaform Technologies’ design and manufacturing expertise streamlines your project, saving you time and money.

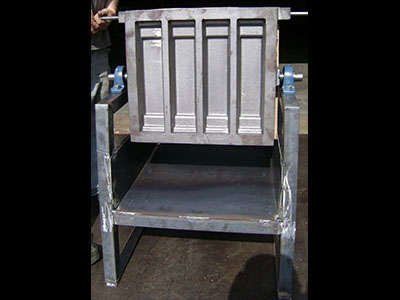

Samples of Recent PIG Mold Projects

- Ductile Iron 2,000 lb Lead Sow Molds

- Cast Iron Air and Water Cooled Anode Molds

- Cast Iron Air and Water Cooled Babbitt Molds

- Cast Iron Air and Water Cooled Solder Bar Molds

- Cast Iron Air and Water Cooled Tin Molds

- Ductile Iron Air Cooled Gold Molds

- Ductile Iron Air Cooled Silver Molds

- Ductile Iron Aluminum Ingot Molds

- Ductile Iron Aluminum Sow Molds

- Cast Iron Billet Molds

- Cast Iron Copper Molds

- Cast Iron Wirtz Style Lead Conveyor Molds

- Cast Iron Lead Ingot Molds

- Cast Iron Lead Pig Molds

- Ductile Iron Lead Sow Molds

- Cast Iron Sample Disc Molds

- Ductile Iron Slag Molds

- Spectrograph Disc Molds

- Zinc Conveyor Molds

- Zinc Sow Molds

- Cast Iron 2″ Ball Molds

- Cast Iron 1-5/8″ Ball Molds

- Aluminum Air Cooled Tin Anode Molds

- Ductile Iron Lead Slag Molds